KUKKO Werkzeugfabrik

Kleinbongartz & Kaiser oHG

Introduction

Products

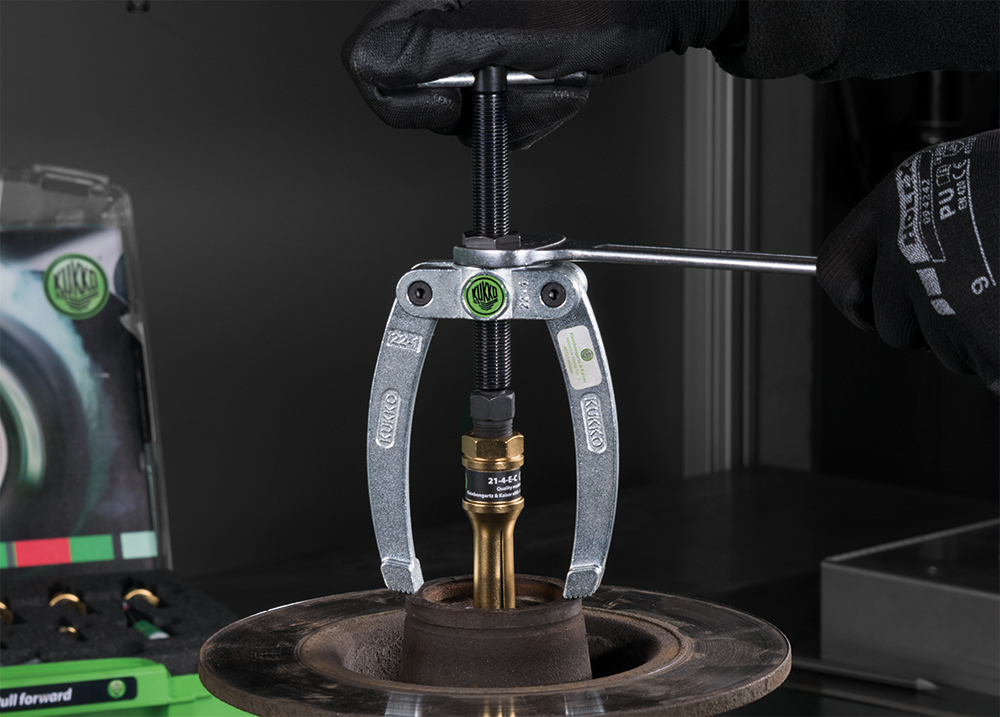

EXTERNAL EXTRACTION

100 percent proven worldwide. Original KUKKO pullers are the best choice for nondestructive disassembly, for example of roller bearings, bearing shells, gear wheels and pulleys. They grip the part that needs to be removed and rest on the shaft without damaging it. With its unique wide range of extractors known worldwide, KUKKO always has the optimal solution for every field of application.

More info

INTERNAL PULLING

100 percent effective power. The KUKKO internal extractors are the solution for parts that are located in a recess, but not on a shaft – for example, roller bearings, sliding bearings and silent bearings. They grip the part from the inside, which can then be pulled out by pulling or striking. KUKKO is a guarantee of high performance and a long service life.

More info

DISASSEMBLY

100 percent careful disassembly. The intelligent KUKKO solution for disassembling ball bearings of any type, which are inside a casing and on a shaft at the same time. Whether ball bearings, slide bearings, silent bearing, sockets, bearing race rings, gears or pulleys – every part can be disassembled without disassembling the shaft. Even if it is not possible to place the spindle on the shaft, the KUKKO slide hammer can be used in combination to ensure contact-free and gentle removal.

More info

AUTOMOTIVE

100 percent effectiveness. KUKKO knows the special challenges of every automotive workshop. Engine compartments are becoming increasingly narrow, repair zones increasingly inaccessible and the mechanics increasingly complex. For highly demanding disassembly in the chassis area, KUKKO has developed very special puller and ejector solutions. The gripping of the joint and removing or pressing out until the ball is released is carried out carefully and with maximum efficiency.

More infoInsights

Contact

Website

kukko.comLocation

KUKKO Werkzeugfabrik Kleinbongartz & Kaiser oHG

40721 Hilden

GERMANY

F: 02103 9754-310

The content of this page is under responsibility of the respective company.